Citius - Condition Based Monitoring e Line Supervision

Real-time supervision and predictive maintenance in a single platform

In the modern industrial landscape, production management requires more than just data collection — it needs visibility, control, and predictive insights.

The Condition Based Monitoring and Line Supervision software by Len Solution brings these capabilities together in one integrated platform that helps manufacturers supervise, analyze, and predict, boosting productivity, reducing downtime, and optimizing performance.

The challenge: from fata to actionable Iintelligence

From raw data to informed decisions

Every machine generates huge volumes of data — but data alone doesn’t create value.

True value comes from analyzing and transforming that data into decisions and actions.

Many companies still face:

-

Costly, unplanned downtime

-

Limited process visibility

-

Lack of real-time performance analysis

-

Decisions made on intuition rather than evidence

Len Solution’s Condition Based Monitoring and Line Supervision software tackles these issues by combining production supervision and predictive maintenance in one powerful tool.

Len Solution’s vision: Supervise. Predict. Improve.

Two core functions, one integrated platform

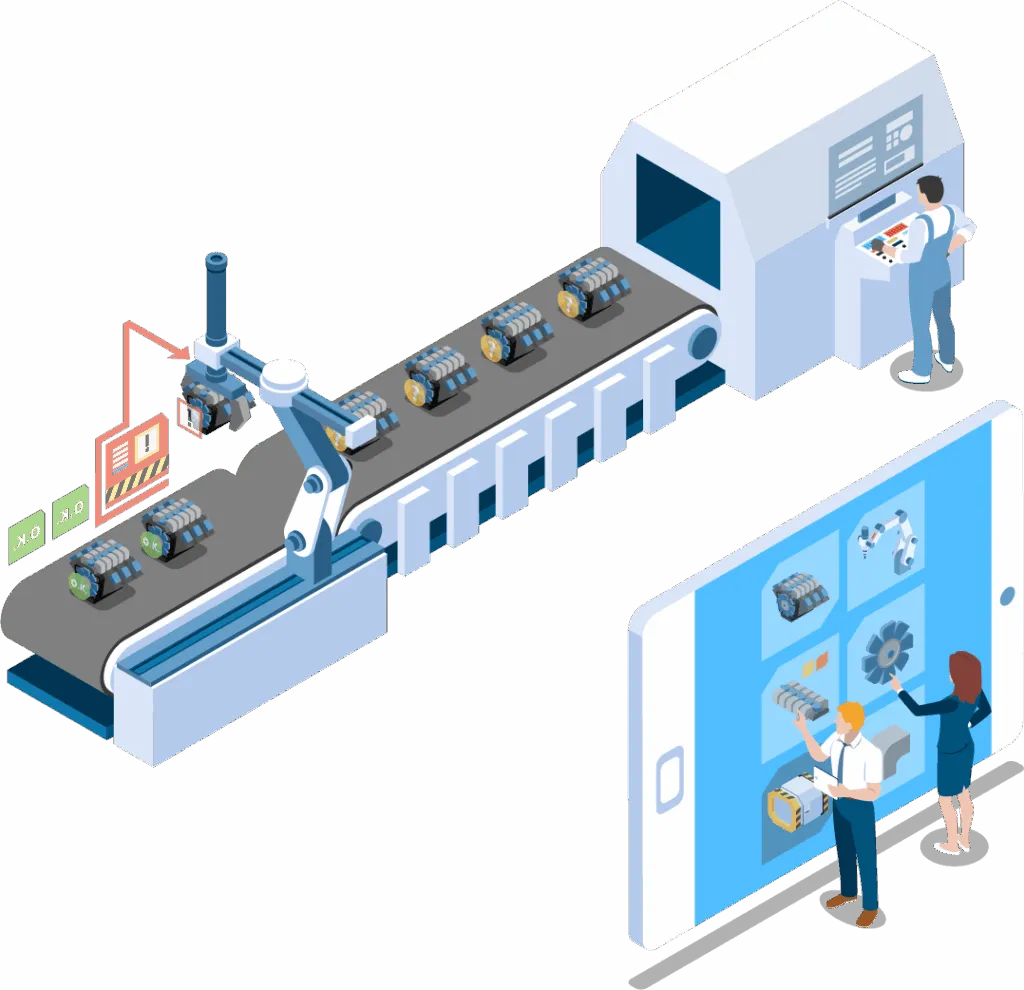

The solution unites two strategic components:

-

Line Supervision → Real-time control of production processes

-

Condition Based Monitoring (CBM) → Predictive analytics for machine health

From factory floor to management systems, every layer is connected and data-driven, creating a flexible ecosystem tailored to any industrial context.

Citius: Condition Based Monitoring and Line Supervision

What Is Line Supervision?

Full control of your production in real time

The Line Supervision module acts as the operational core of the factory.

It connects machines, operators, and management systems, offering complete process visibility.

With this system, you can:

- Monitor machine and line status in real time

- Track cycle times, stops, and alerts

- Automatically record parameters and batches

- Coordinate machines and operators efficiently

Track cycle times, stops, and alerts

Automatically record parameters and batches

Coordinate machines and operators efficiently

Key Benefits of Line Supervision

- Complete visibility on OEE, performance, and downtime

- Instant identification of bottlenecks and inefficiencies

- Full traceability for compliance and quality control

- Continuous improvement supported by dynamic KPIs

Result: smoother operations, faster decisions, and improved productivity.

What Is Condition Based Monitoring (CBM)?

Turning monitoring into intelligent prediction

Condition Based Monitoring continuously tracks the health of industrial machines, detecting anomalies and predicting failures before they happen.

Using IoT sensors, industrial gateways, and predictive algorithms, the system collects and analyzes parameters such as:

- Vibrations

- Temperature

- Pressure

- Power consumption

- Acoustic noise

- Lubrication levels

The CBM software detects abnormal patterns and recommends data-driven maintenance actions to avoid unexpected breakdowns.

Benefits of Condition Based Monitoring

- Reduced unplanned downtime

- Extended asset lifespan

- Optimized maintenance costs

- Improved reliability and safety

Result: predictive, stable, and continuous production.

Designed for Industry and People

Flexible, modular, and user-friendly

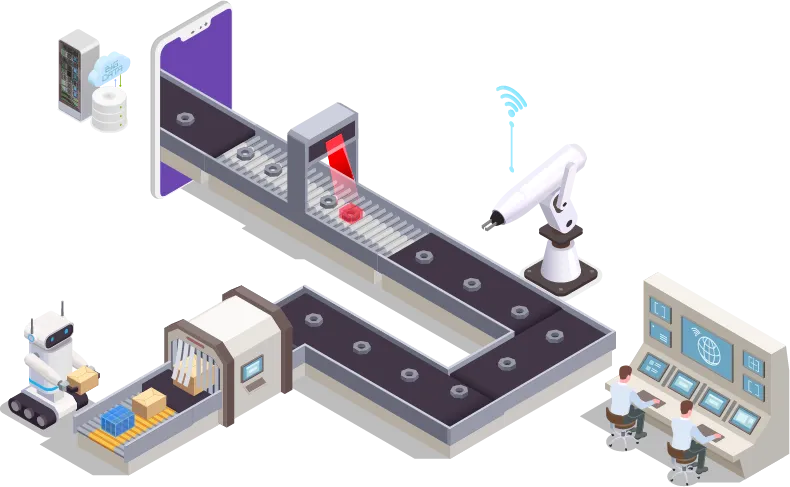

The Condition Based Monitoring and Line Supervision software by Len Solution is built to be scalable and customizable, adapting seamlessly to any production environment.

-

Customizable – tailored to your machines and processes

-

Modular – activate only the features need

-

Compatible – works with Siemens, Beckhoff, Rockwell, and other PLCs

-

Deployable – on-premise or in the cloud

Intuitive Interfaces and Real-Time Dashboards

The system offers personalized dashboards for:

-

Complete production line visualization

-

Machine-level performance analysis

-

Configurable KPIs, thresholds, and alerts

Operators and managers gain a clear, actionable view of the entire plant.

Benefits for Your Business

From monitoring to strategic intelligence

Adopting a Condition Based Monitoring and Line Supervision software means transforming data into measurable value.

Key advantages include:

-

Higher OEE and productivity

-

Reduced downtime

-

Data-driven decision-making

-

Enhanced process quality and traceability

-

ROI in months, not years

The synergy between supervision and CBM moves your company from reactive control to proactive improvement.

Why Choose Len Solution

Your partner for connected manufacturing

With years of experience in developing software solutions for logging and processing high-frequency and high-volume data, and in building applications for Industry 4.0, Len Solution supports companies in the digitalisation of industrial processes through tailor-made technologies.

The CBM & Line Supervision platform is:

-

Reliable – built to industrial standards

-

Scalable – suitable for both single lines and multi-site facilities

-

User-friendly – intuitive for both operators and managers

-

Sustainable – reduces waste, costs, and inefficiencies

The Future of Smart Manufacturing

From supervision to prediction — all in one solution

Len Solution’s Condition Based Monitoring and Line Supervision software is more than a monitoring tool — it’s the digital backbone of your production.

It allows you to predict, optimize, and evolve, turning your factory into a connected, efficient, and intelligent system.

Contact us today for a free consultation or request a live demo.

Supervise. Predict. Improve. With Len Solution.